Our Excellent Produce Process——Wonderful Carbon Fiber Pole

Introduction Of Our Produce Process

1.Pattern Cutting

The Pre Preg is cut into specific shapes known as patterns which vary in shape, size and type of weave of cloth. The Tube design is very much affected by the 'cut of the cloth,number of layers and the patterns used. These patterns are cut using the computer controlled plotting machine to very high accuracy and very tight tolerances.

2. Rolling Tube

The edges of the cut patterns are adhered to the mandrel with pressure to fix the leading edge of the patterns to the mandrel. Then mandrel with carbon fibre patterns loaded is then rolled between the plates of a special high pressure table to ensure that the patterns are tightly compacted without any rucks or ridges giving a uniform surface finish.

4. Pressure taping

The rolled carbon tube on the mandrel is then spun whilst applying the heat shrink wrap cellophane tape adding the pressure onto the mandrel with great force. The heat shrink wrap process gives the very fine circular textured finish which you will see in un-sanded carbon tubes.

5. Curing

The mandrels loaded with the completed heat shrink wrapped tube is now ready to be cured and are loaded into an oven for the curing process to take place. This process is a very controlled process which ensures that the resin in the cloth flows and the shrink wrapping squeezes the cloth leaving only a small amount on the outside surface of the tubes.

The loaded mandrels are then removed from the oven after which the mandrels are drawn outleaving the hollow carbon tube ready to be trimmed, sanded, painted or stored ready for shipping. The mandrels have good durability and can be used many many times.

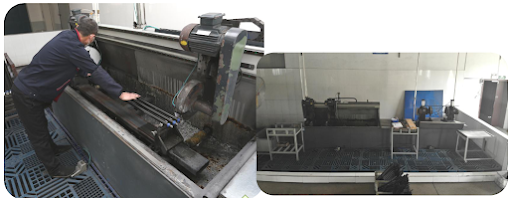

7. Tape removal

The heat shrink tape is removed by high pressure water blasting which strips the heat shrink tape leaving a uniform consistent surface finish with the tube is ready to use. It can be mechanically ground to size or go to have paint coating to be applied or go with the tube in its natural finished state.

8. Optional surface finishing/painting

If a customer requires the optional surface, sanded surface is available. A coloured surface finish can be painted too.

9. Cutting

The two ends will be cut off. And the tubes will be given at designed length.

.JPG)

.JPG)

评论

发表评论